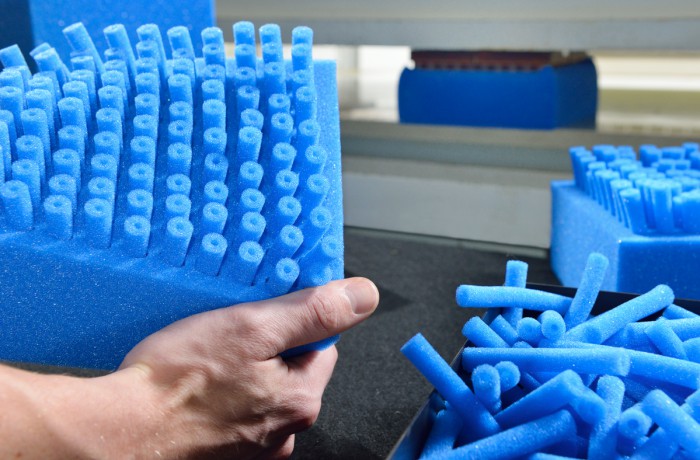

These work steps are mainly used to manufacture products for the engineering, medical or packaging industries. Drill holes are used in a number of applications; they make it possible, for instance, to cut foam tubes to custom lengths without requiring adhesive joints. We also use various milling techniques. In the simple method, a milling head removes material along a template. This method enables a wide variety of complex geometries. Yet there is another, more sophisticated method that uses a fully automatic four- or multi-axial milling machine. Even though such machines are primarily used in the metalworking industry, they are equally suitable for foam conversion because they enable production of exceedingly sophisticated profiled items. Pressing is another option to manufacture profiled products, including both laminated parts (equipped with self-adhesive films or nonwovens) and non-laminated items. Celloflex operates beam press systems and swing-beam presses for this purpose.