Polyurethane (PU) foam is produced from polyols and toluylene diisocyanate (TDI) or methylene diphenyl isocyanate (MDI), which are polyisocyanates supplied by the petrochemical industry. Two different input materials, slabstock and moulded foam, are used for fabricating flexible polyurethane foam. Celloflex exclusively uses cut-to-size slabstock, which is associated with a number of advantages: firstly, the moulded foam process is very costly because it requires sophisticated tools, which makes this technique commercially viable only if items are produced in very large quantities. Secondly, this process eliminates some of the favourable characteristics of the foam, which include its breathability and flexibility.

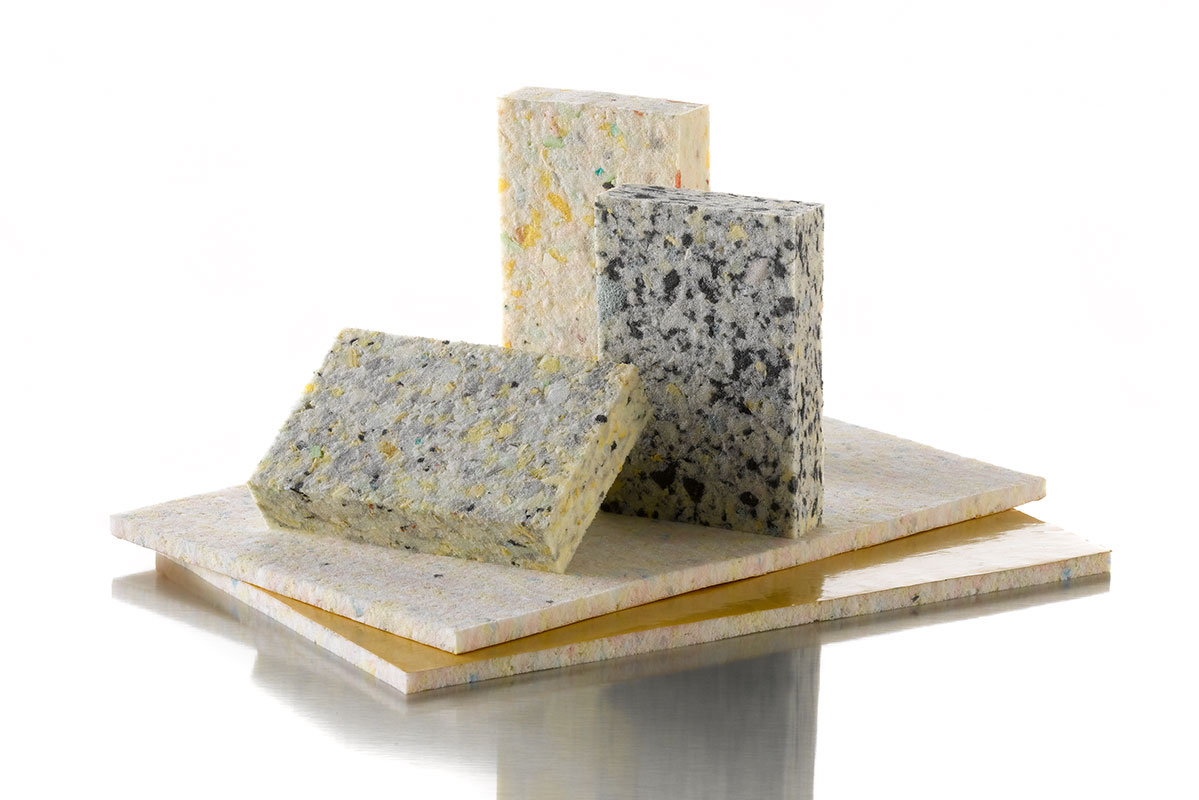

PU foam is highly elastic and porous whilst having a relatively low weight, which makes it differ from a large number of other materials. This is why foam is favoured for a wide range of applications in many industries.

Polyurethane foam production

In the slabstock fabrication process, a reactive mixture comprising polyols and isocyanate is applied to a paper-clad conveyor in a traversing movement. This blend is combined with water as a foaming agent to trigger a chemical reaction in which the mixture expands to 60 times its original volume. Selection of appropriate input materials is the key to determining the characteristics of the finished foam product. The long slab created during the foaming process is about 2 m wide and 60 m long. Its height varies according to the specific foam grade. This long slab is then put to interim storage in a curing chamber until the reaction chain is completed. In the next step, the slab is cut to the required length. Our core area of expertise is to customise such foam slabs in various ways to make them suitable for any conceivable application.

Our key strength that makes us stand out from other foam converters is our ability to provide PU foams that exhibit a wide variety of properties. Among the 75 grades that we keep on stock on a permanent basis are a number of foams with particular characteristics such as flame-resistant (MVSS 302, CMHR, Crib V) or antistatic properties. This range is complemented by polyether and polyester foams, viscoelastic foam, sponge foam, reticulated filter foam and many other varieties.