Self-adhesive films or items fitted with self-adhesive backings are becoming increasingly popular in many areas, particularly in various engineering fields. They enable clean and easy assembly of a wide variety of components. Self-adhesive films usually comprise two components: the carrier and the adhesive. Either of these can consist of a wide range of materials. Adhesives can either contain solvents or be solvent-free. Celloflex always uses solvent-free adhesives. Self-adhesive films or double-sided adhesive tapes essentially use two types of adhesives: rubber resin or acrylic adhesives. These are water-based dispersion adhesives. Between 40 and 70% of the water evaporates when applying the adhesive.

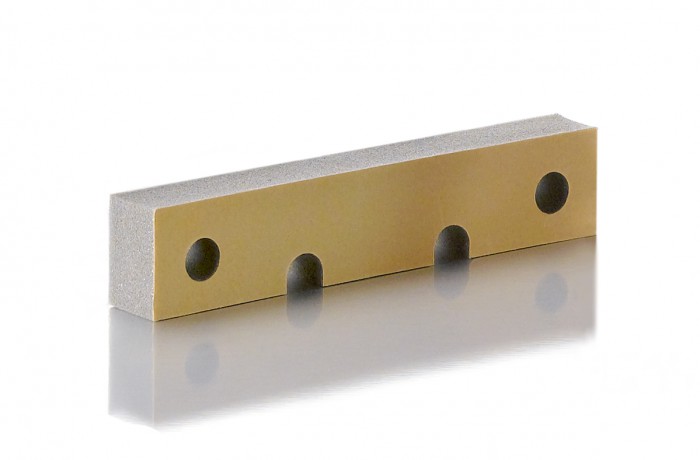

Carriers can consist of a wide variety of materials, including fibres or nonwovens but also silicone-coated separation films. A distinction should be made between components or items equipped with self-adhesive backings (with the aim to attach the component to another item using an adhesive) and materials that include a nonwoven or similar layer. Celloflex offers both options to provide additional features or to make assembly easier when cutting foam to size.